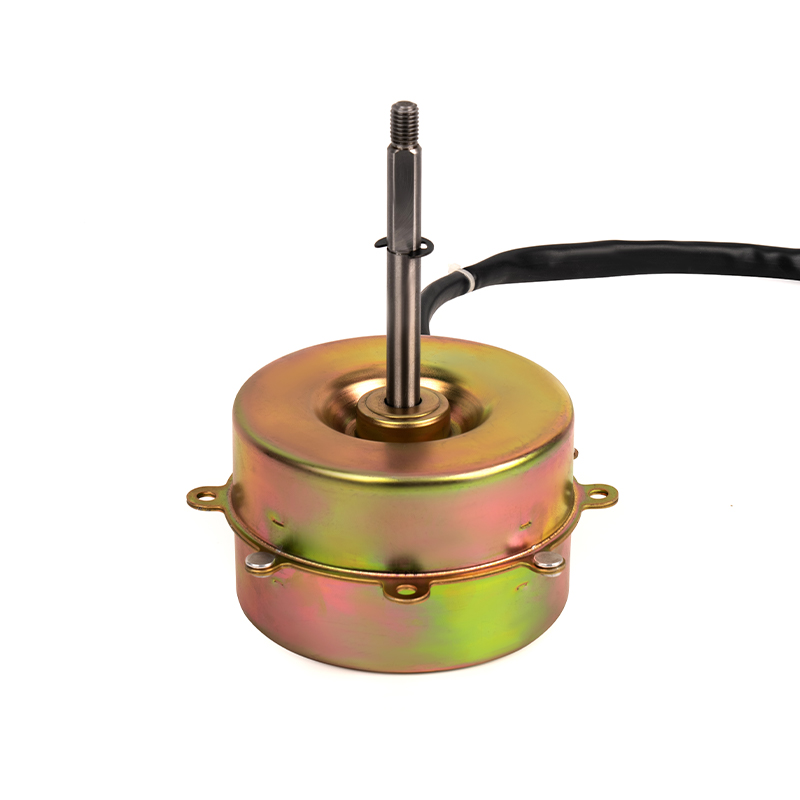

Fan Operation: The Dehumidifier Motor powers the fan, which is the first step in the moisture removal process. The fan draws air from the room and directs it through the unit, where it passes over the evaporator coils. The motor's role in driving the fan ensures that air is constantly circulated through the system, which helps to maintain a consistent flow of air. This continuous airflow is essential for ensuring that enough moisture-laden air comes into contact with the cold evaporator coils, where the dehumidification process begins. If the fan does not operate effectively, the overall moisture removal capacity of the unit will be significantly reduced.

Evaporator Coils and Refrigerant: The Dehumidifier Motor drives the fan, which pushes air over the evaporator coils. These coils are cooled by the refrigerant circulating inside them. As warm, moisture-laden air flows over the cold coils, the temperature of the air drops, causing the water vapor in the air to condense. This is the primary mechanism of moisture removal. The condensed water then collects in a reservoir or is expelled through a drainage system. The efficiency of this process depends on the continuous flow of air provided by the fan, which is driven by the Dehumidifier Motor. The more effectively the air flows across the coils, the greater the volume of moisture that can be removed from the air.

Compressor Function: While the Dehumidifier Motor does not directly power the compressor, it plays an indirect but critical role in supporting the compressor's function. The compressor pressurizes the refrigerant gas, which is necessary for the refrigerant to circulate through the system. Once the refrigerant passes through the evaporator coils and absorbs heat, it needs to be compressed and moved to the condenser coils, where it can release its heat and moisture. The Dehumidifier Motor ensures that the air moves effectively over the coils, aiding the overall cooling and heating cycle. The efficient operation of the motor ensures that there is sufficient airflow to help the compressor function optimally, leading to better moisture removal and more effective dehumidification.

Heat Exchange Process: After the air is cooled and moisture is condensed on the evaporator coils, the refrigerant moves to the condenser coils, where it releases the absorbed moisture and heat. The Dehumidifier Motor drives the fan that blows air over the condenser coils, facilitating the heat exchange process. By expelling heat from the system, the motor helps maintain the efficiency of the dehumidification cycle. If the condenser coils are not adequately cooled, the refrigerant may not release heat effectively, which can reduce the overall performance of the dehumidifier. The Dehumidifier Motor ensures that the air around the condenser coils is constantly moving, promoting efficient heat dissipation and ensuring the unit operates at peak performance.

Continuous Airflow: The Dehumidifier Motor is responsible for maintaining a steady airflow throughout the dehumidification process. This is essential not only for moisture removal but also for the overall efficiency of the unit. The continuous movement of air allows for a consistent rate of evaporation, which in turn keeps the refrigerant circulating and the cooling process efficient. Without this continuous airflow, the evaporator and condenser coils may not function optimally, reducing the unit's capacity to remove moisture. The motor ensures that both the evaporator and condenser coils receive adequate airflow, maximizing moisture extraction and maintaining consistent humidity levels.

Energy Efficiency and Performance: The Dehumidifier Motor plays a significant role in balancing the dehumidification process with energy efficiency. A high-quality motor ensures that the fan operates at an optimal speed, providing sufficient airflow without unnecessarily consuming excessive energy. In conjunction with the compressor and evaporator, the motor helps to ensure that moisture is effectively removed from the air while keeping energy usage within reasonable limits. By regulating the airflow, the motor contributes to reducing the strain on the compressor, leading to more efficient energy consumption and better overall performance. Units with energy-efficient motors can maintain optimal dehumidification levels while minimizing electricity costs, making them a more sustainable and cost-effective solution for long-term use.

English

English عربى

عربى ++86-13524608688

++86-13524608688